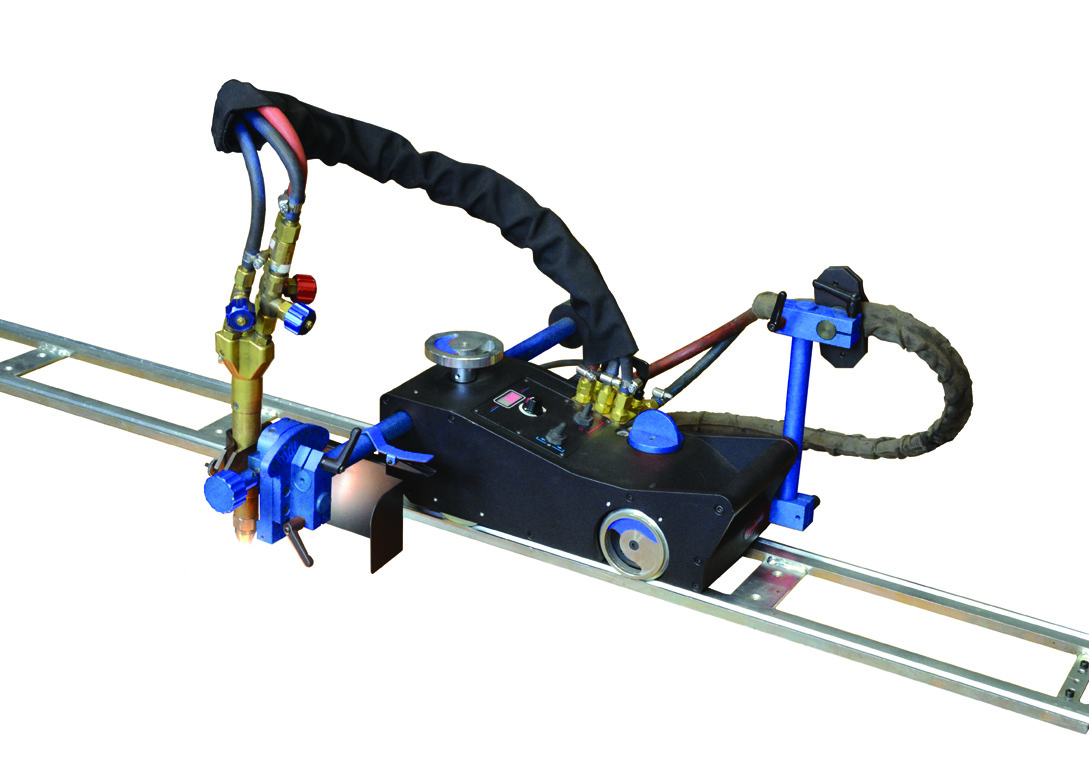

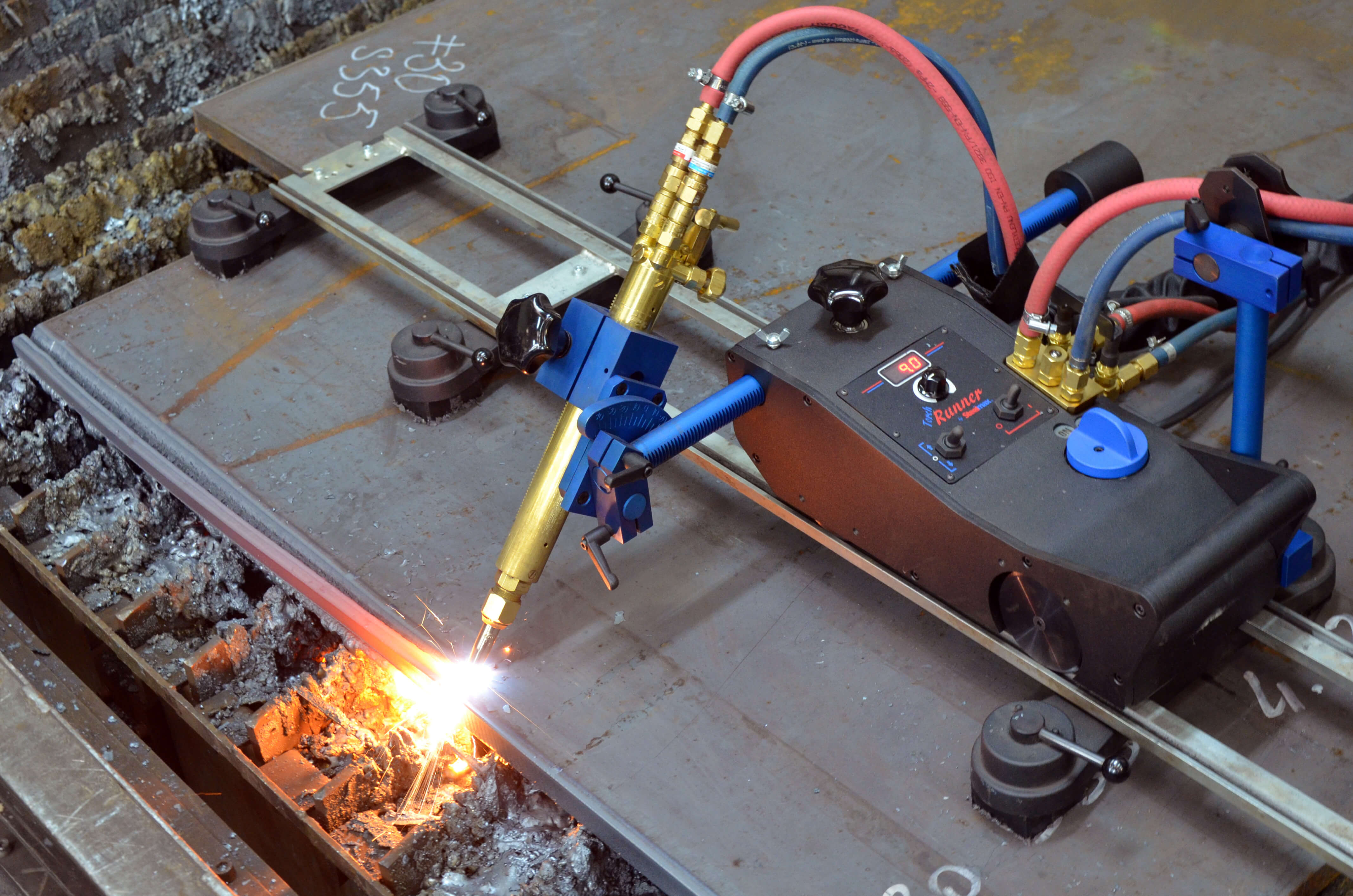

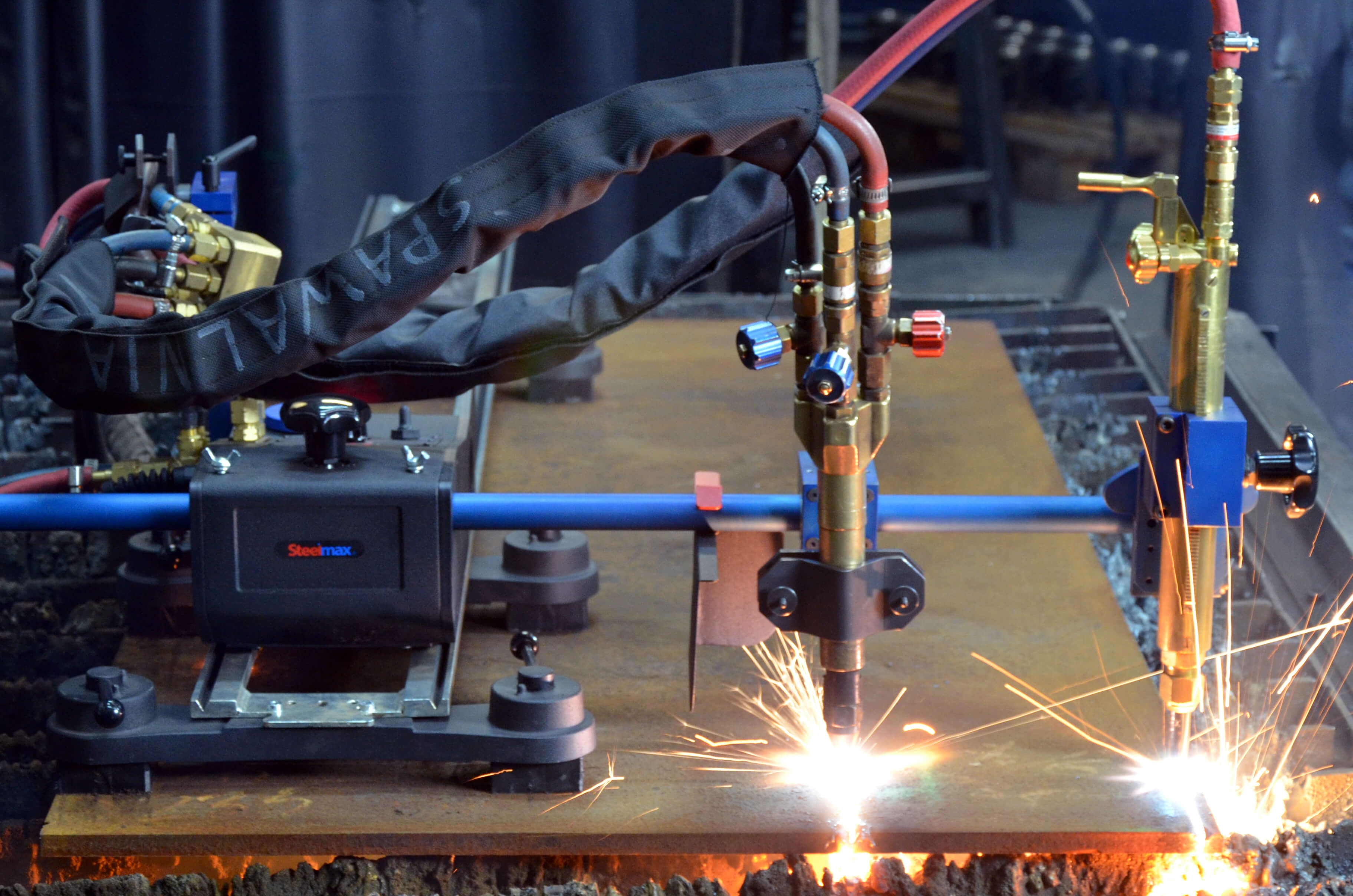

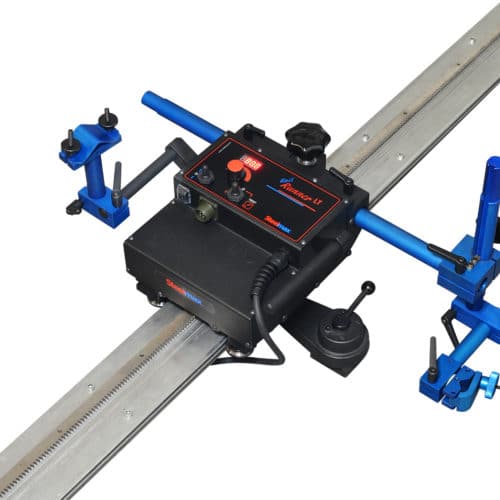

The Steelmax® Torch Runner is a state-of-the-art, digitally controlled track torch which maintains precise and stable travel speeds that produce accurate cuts and bevels with oxy-fuel or plasma. The machine can be used on any standard 6″ V-grooved track. Plate cutting and weld preparation can now be done with a high degree of precision. Quality cuts and bevels produced with Torch Runner reduce fit-up and grinding time and lay the foundation for a high quality weld.

The Torch Runner is available in two versions: a standard version for oxy-fuel cutting applications (up to 59 ipm) and a high speed version for plasma cutting applications (up to 118 ipm).

FEATURES

- 1-3/8″ (35 mm) Machine Barrel Torch Holder with precise angle setting up to 45 degrees

- Rigid heat-proof design

- Advanced Speed Control with electronic closed loop feedback for stable speed regulation

- LED Display with readout of actual and preset speed

- Two-wheel drive with braking

- Free wheel clutch system features rapid disengagement of drive mechanism for repositioning

- Interconnecting rails for long cuts and bevels

- Optional gas manifolds for two or three hose torches

- Optional circle cutting attachment

STANDARD KIT INCLUDES:

- Torch Runner drive unit

- Power cord

- Counterweight

- Geared Rack 22.8″ (580 mm) long

- Machine barrel torch holder with precise angle adjustment for torch barrel diameter of 1-3/8″ (35 mm) with 32 pitch gear rack